Transportation Committee

On October 19, 2023, the Liverpool Central School District provided the community with information regarding the transition to electric school buses for the Liverpool Central School District. In alignment with New York State's objective to transition all school buses to zero-emission by 2035, the district is exploring the best path forward with the help of its Transportation Committee.

That evening, community members were presented the following information:

- Introduction and Overview of the NYS Electric School Bus Roadmap.

- Presentation by NY Bus and Girardin Macrobird on electric bus technology and benefits.

- Discussion on the Electric Study from National Grid.

- Insights into the Bus Fleet Analysis study currently being conducted by the power company Enel North America - USA.

Our deep dive into the NYS Roadmap and the subsequent research by our committees will address the vital facets of this transition: infrastructure expansion, fleet transition planning, workforce development, and coordination with electrical grid operators. Our emphasis is on ensuring that this transformation is not just sustainable but also equitable. We're dedicated to making sure our community benefits directly from these changes and that adequate training opportunities exist for a smooth transition.

Download the NYS Roadmap and Guidebook for P-12 Schools to Transition Bus Fleets to Zero-Emission

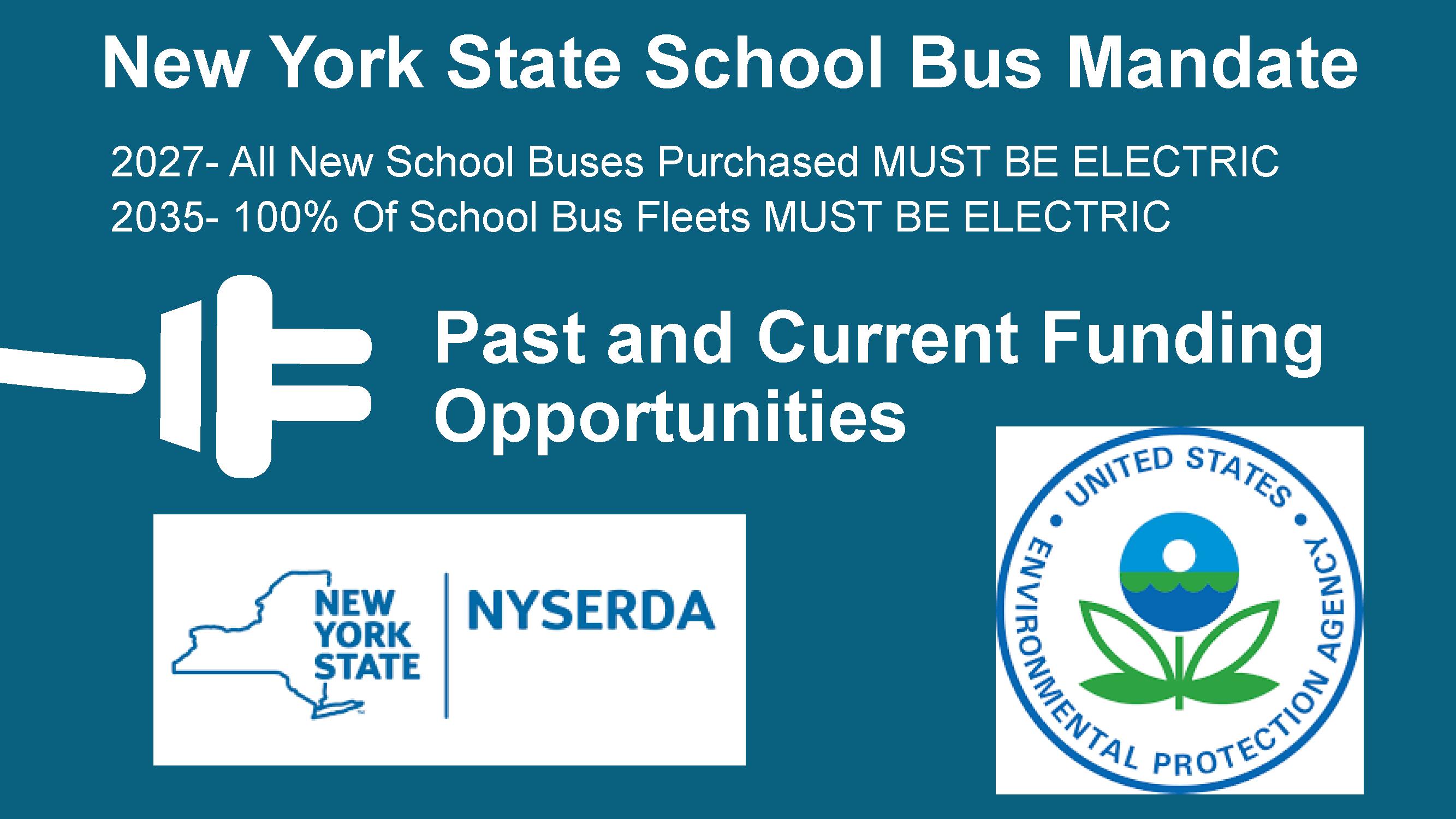

New York State, along with NYSERDA and the EPA, have enacted a school bus mandate. Key milestones:

- 2027 - All New School Bus Purchases MUST BE ELECTRIC

- 2035 - 100% of School Bus Fleets MUST BE ELECTRIC

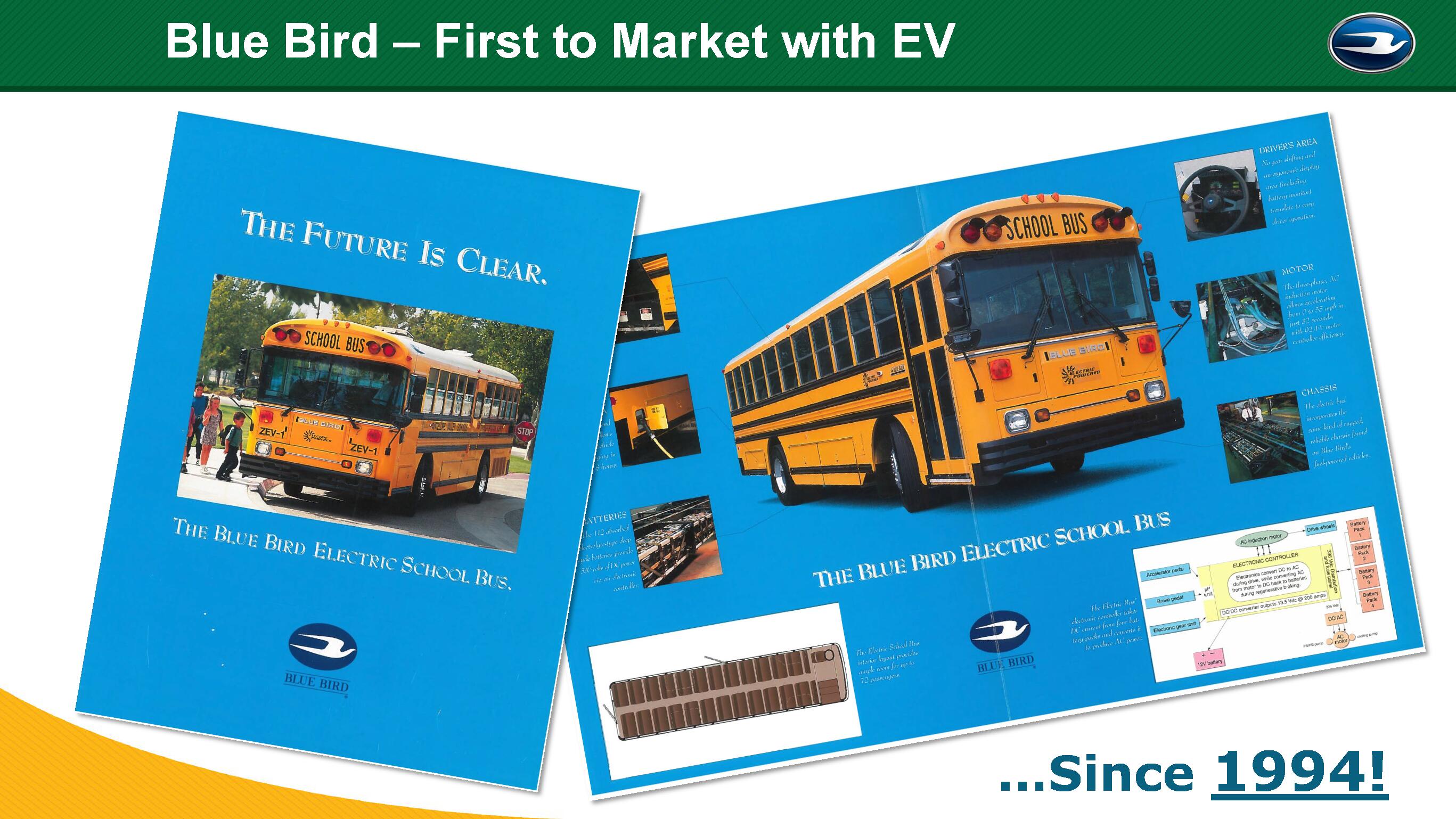

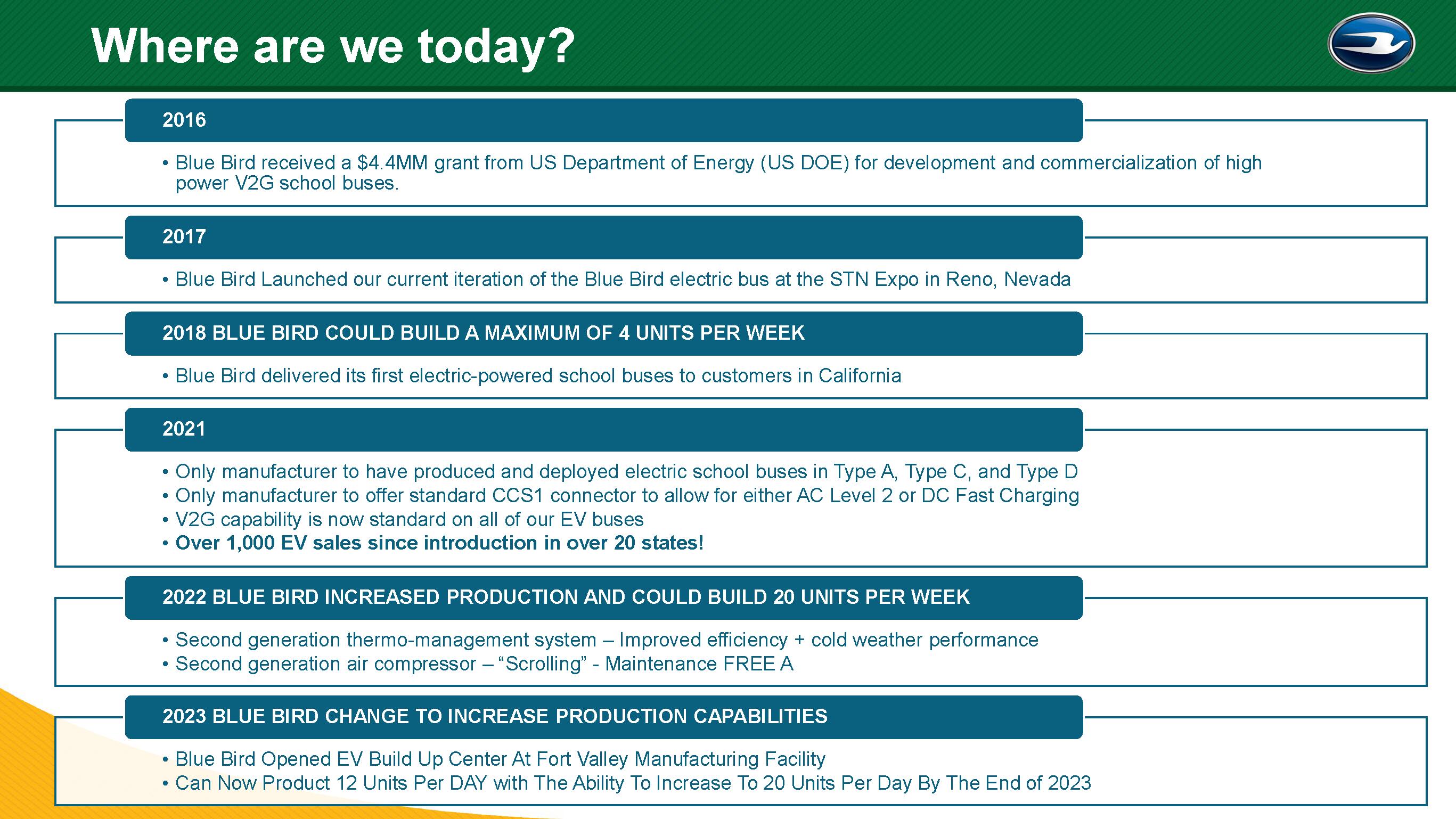

The Liverpool Central School District purchases buses through New York Bus Sales and its fleet consists of Blue Bird buses.

Right now, Blue Bird offers more than 30,000 alt power school buses to more than 2,500 school districts. Alt Power includes:

- Propane

- Gasoline

- CNG

- Electricity

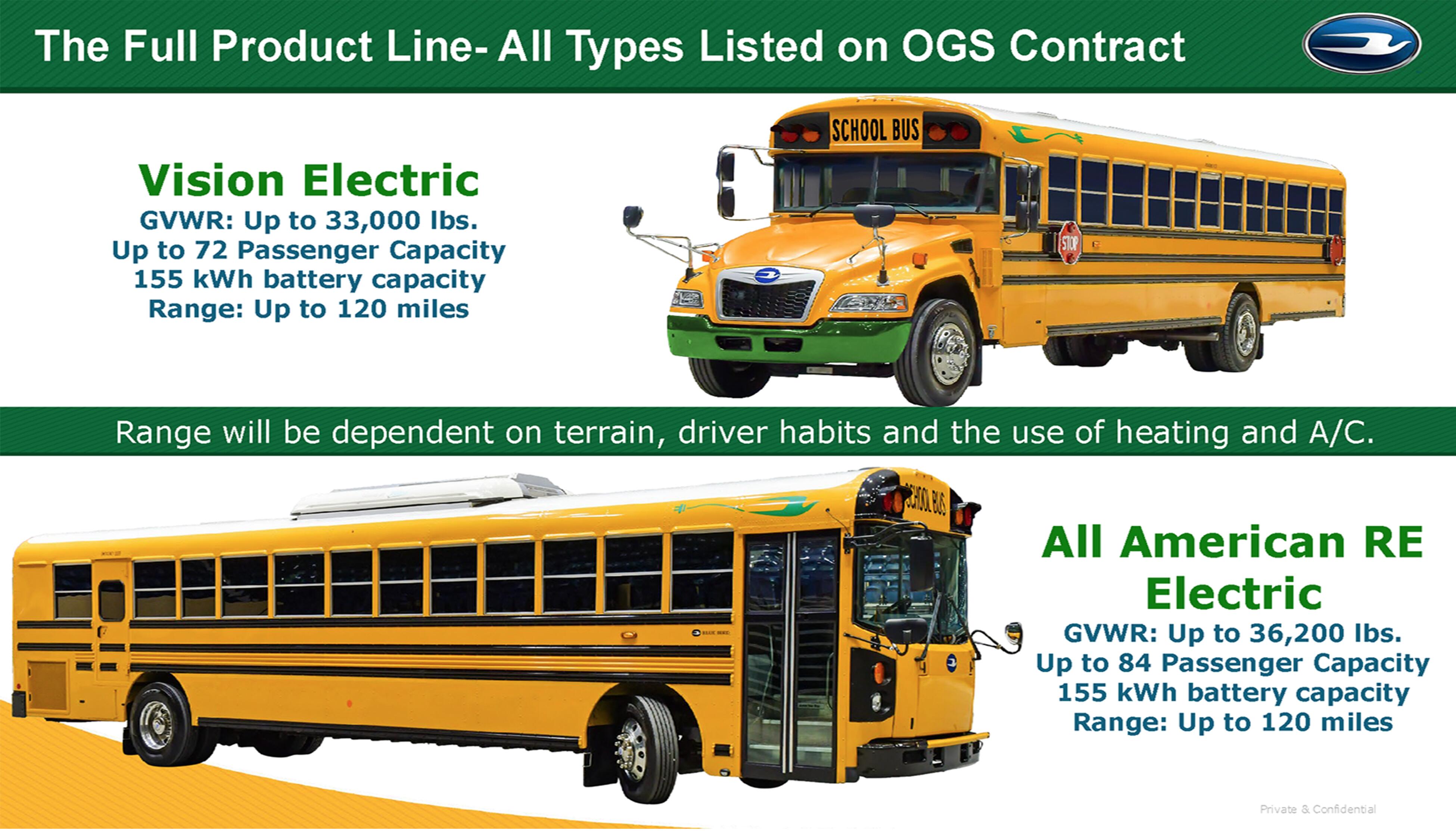

Full Product Line

- Vision Electric

-

GVWR: Up to 33,000 lbs.

-

Up to 72 Passenger Capacity

-

155 kWh battery capacity

-

Range: Up to 120 miles

-

-

All American RE Electric

-

GVWR: Up to 36,200 lbs.

-

Up to 84 Passenger Capacity

-

155 kWh battery capacity

-

Range: Up to 120 miles

-

-

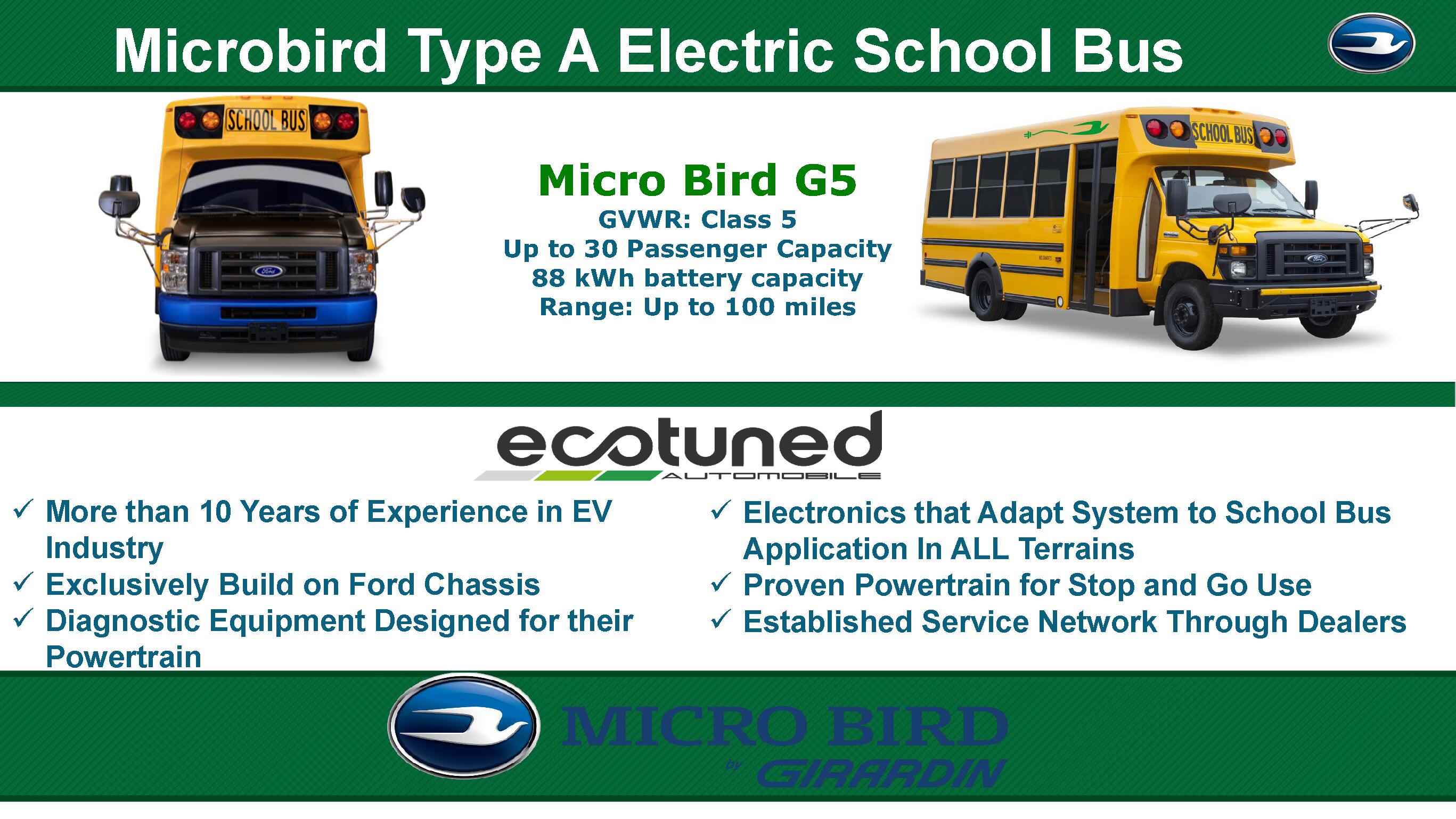

Micro Bird G5

-

GVWR: Class 5

-

Up to 30 Passenger Capacity

-

88 kWh battery capacity

-

Range: Up to 100 miles

-

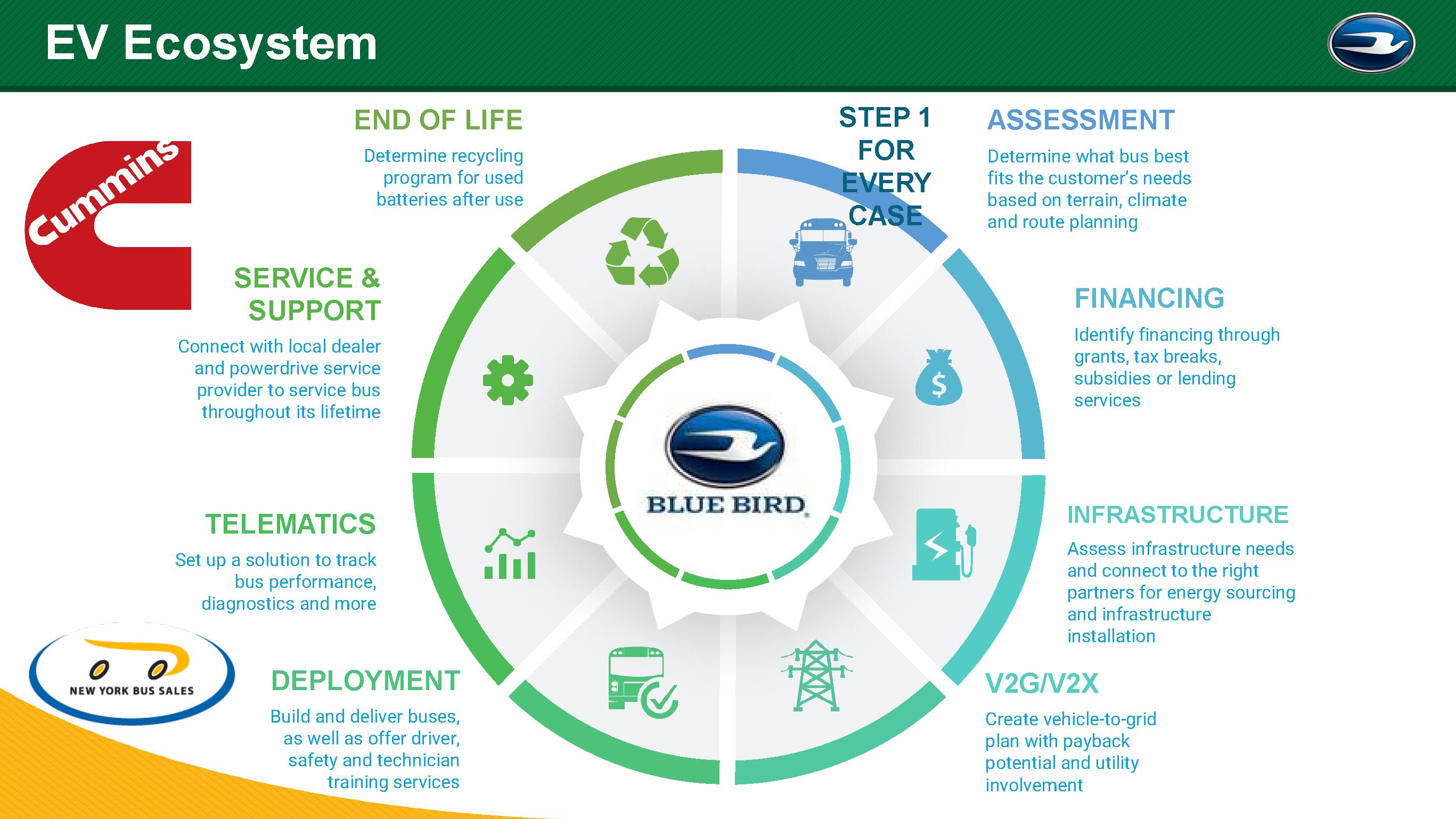

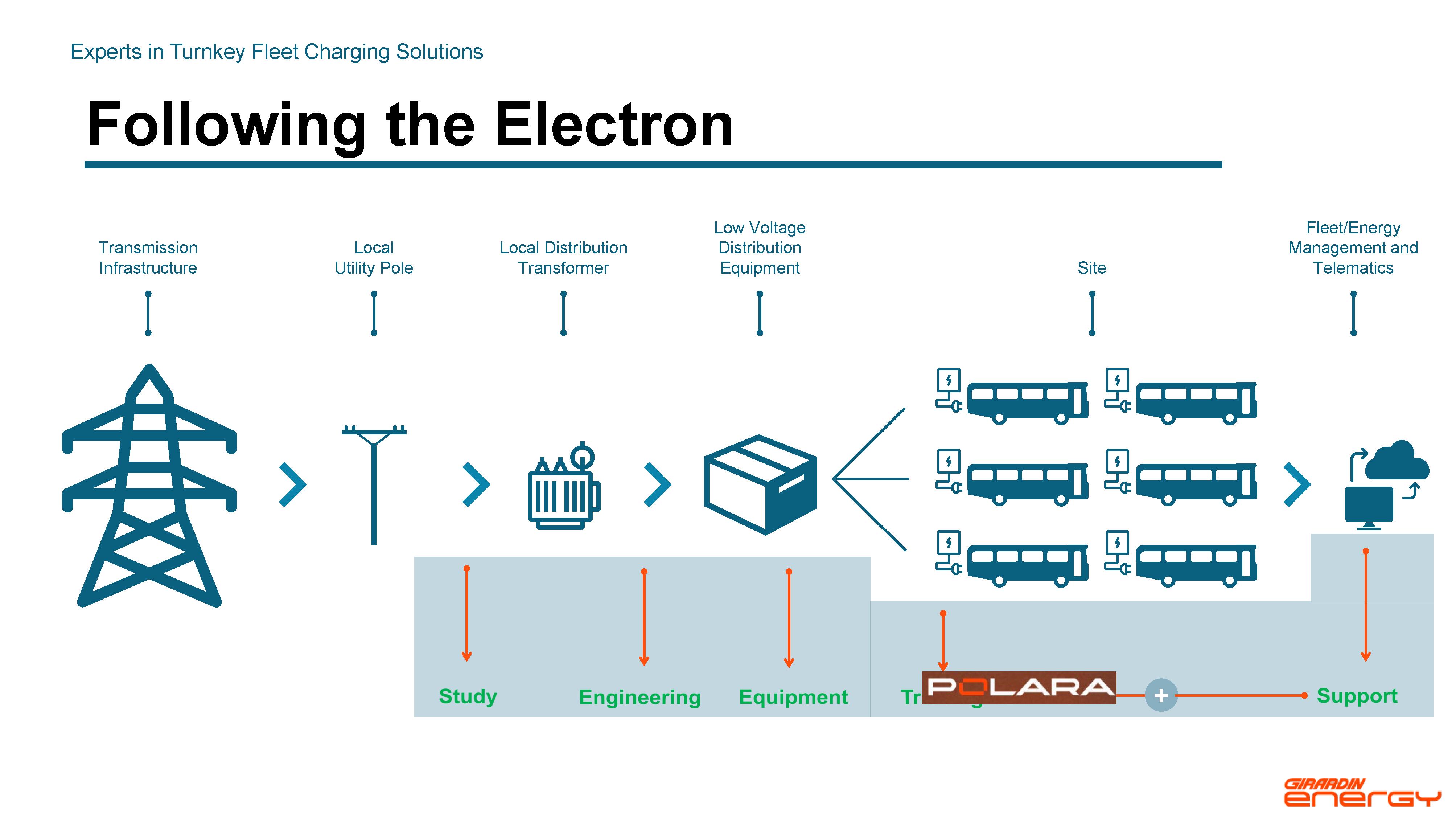

The current EV ecosystem consists of eight steps:

- Assessment: Determine what bus best fits the customer’s needs based on terrain, climate and route planning.

- Financing: Identify financing through grants, tax breaks, subsidies or lending services.

- Infrastructure: Assess infrastructure needs and connect to the right partners for energy sourcing and infrastructure installation.

- V2G/V2X: Create vehicle-to-grid plan with payback potential and utility involvement.

- Deployment: Build and deliver buses, as well as offer driver, safety and technician training services.

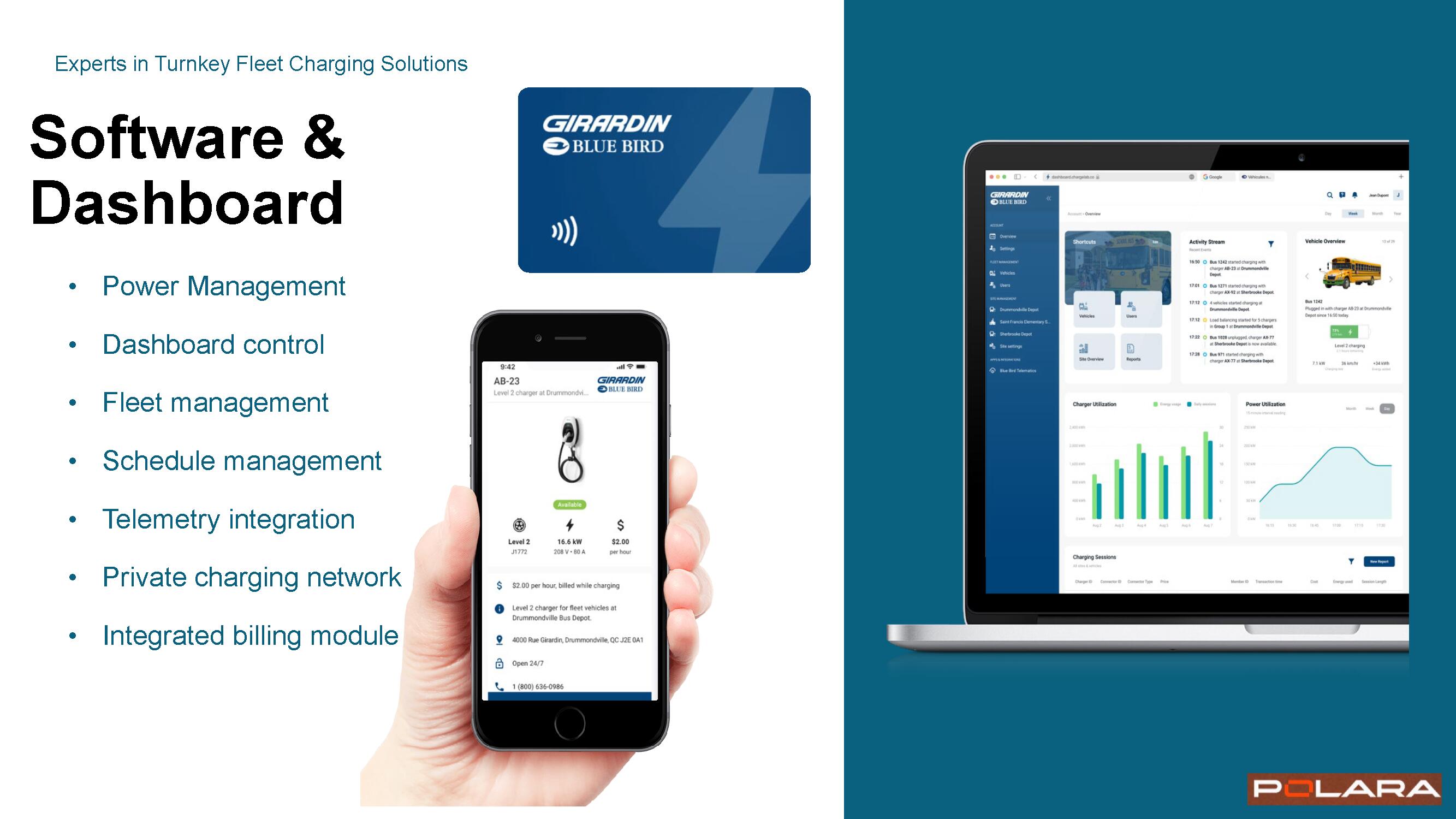

- Telematics: Set up a solution to track bus performance, diagnostics and more.

- Service and Support: Connect with local dealer and powerdriveservice provider to service bus throughout its lifetime.

- End of Life: Determine recycling program for used batteries after use.

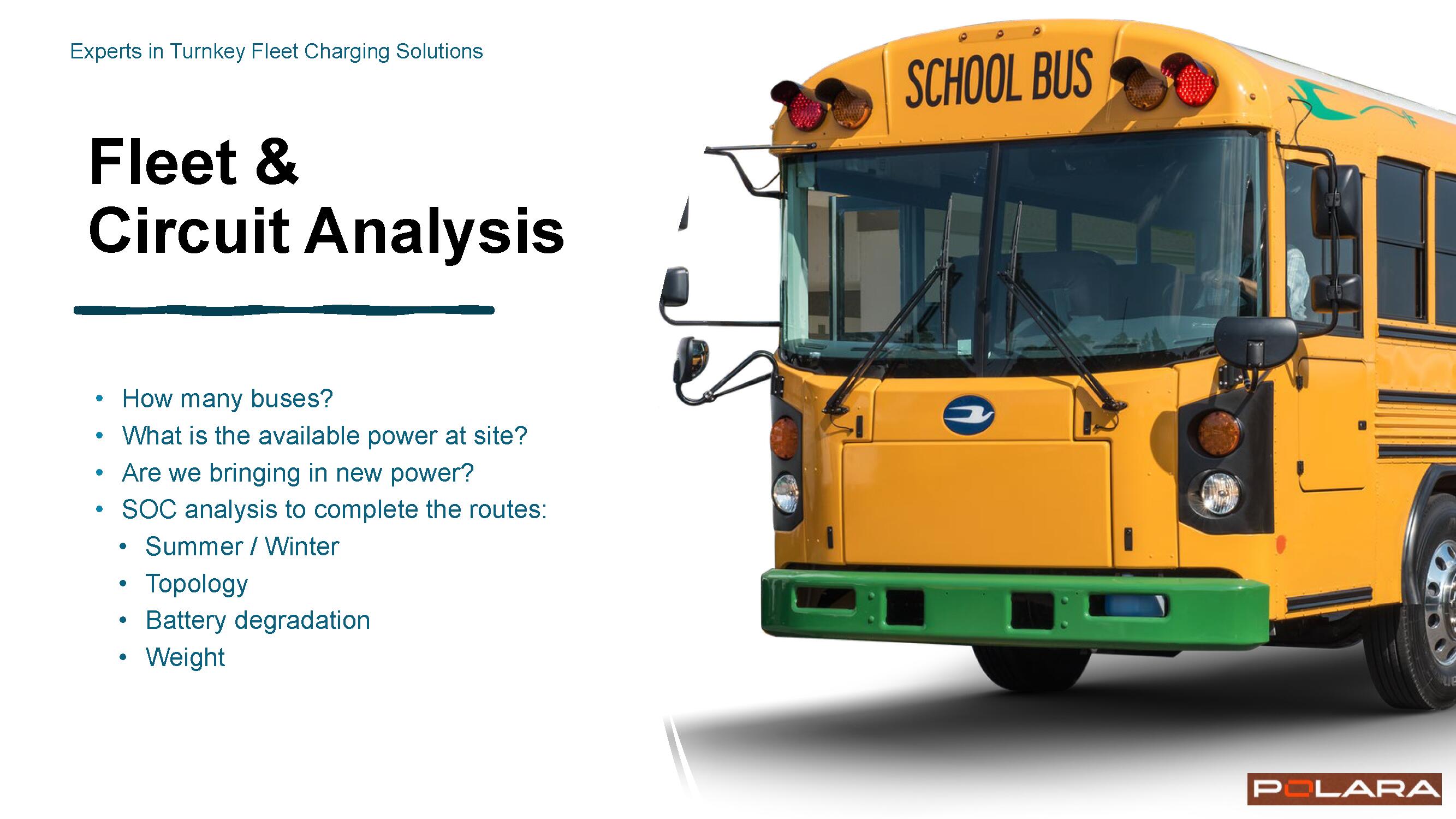

The district will need to analyze its needs in terms of fleet and power:

- How many buses?

- What is the available power at site?

- Are we bringing in new power?

- SOC analysis to complete the routes:

- Summer / Winter

- Topology

- Battery degradation

- Weight

Other topics to analyze are:

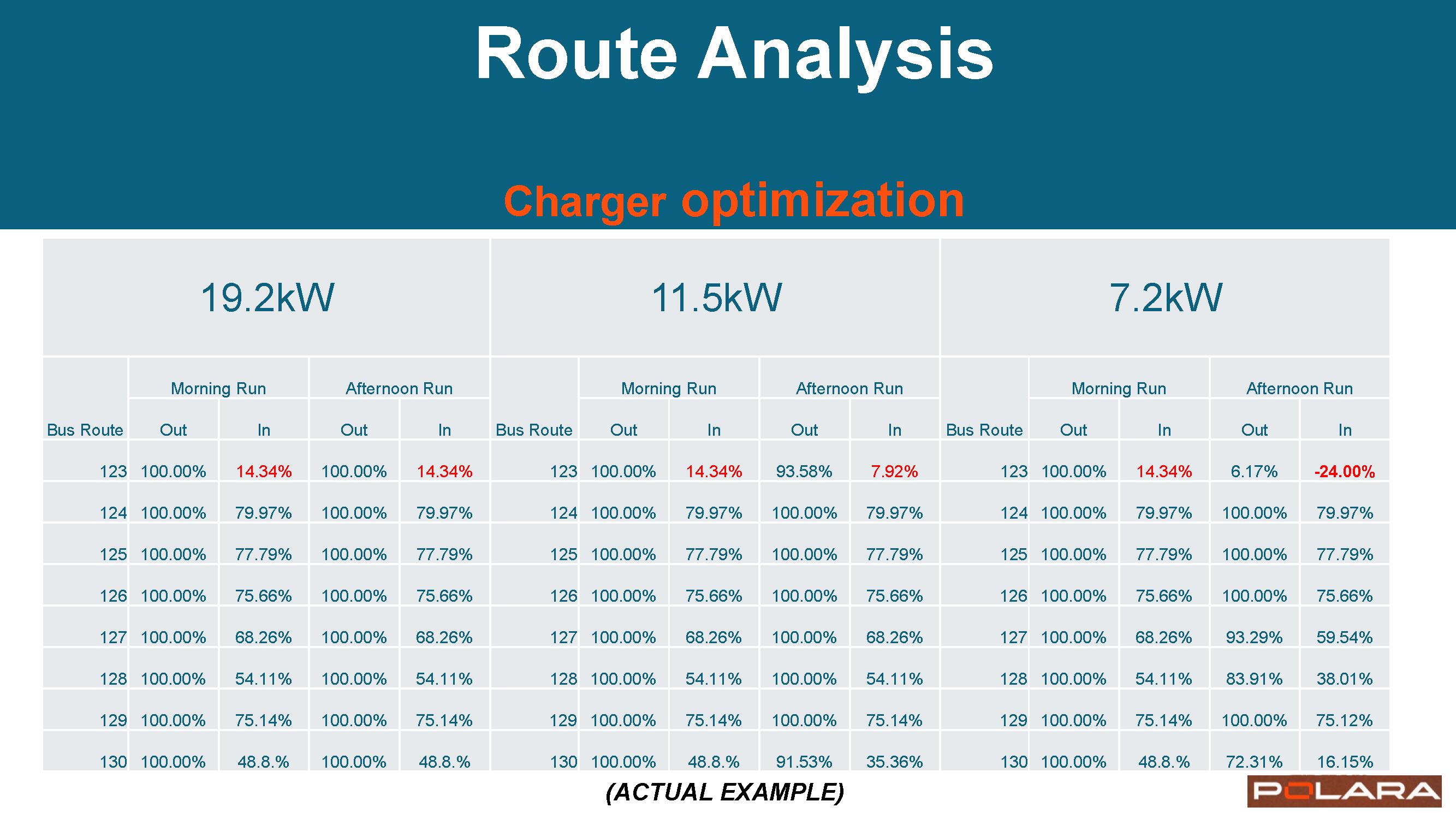

- Charger Optimization

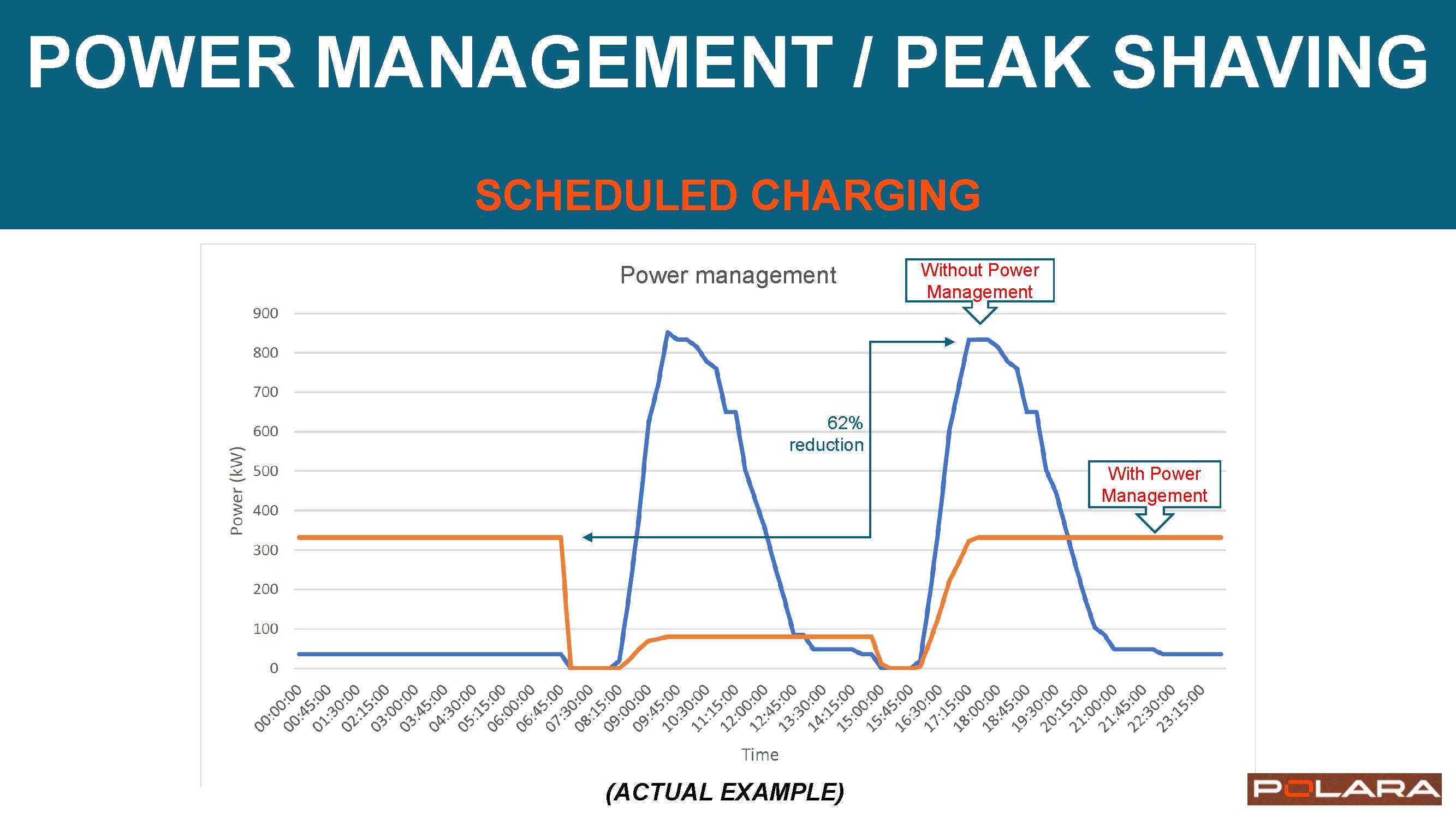

- Scheduled Charging

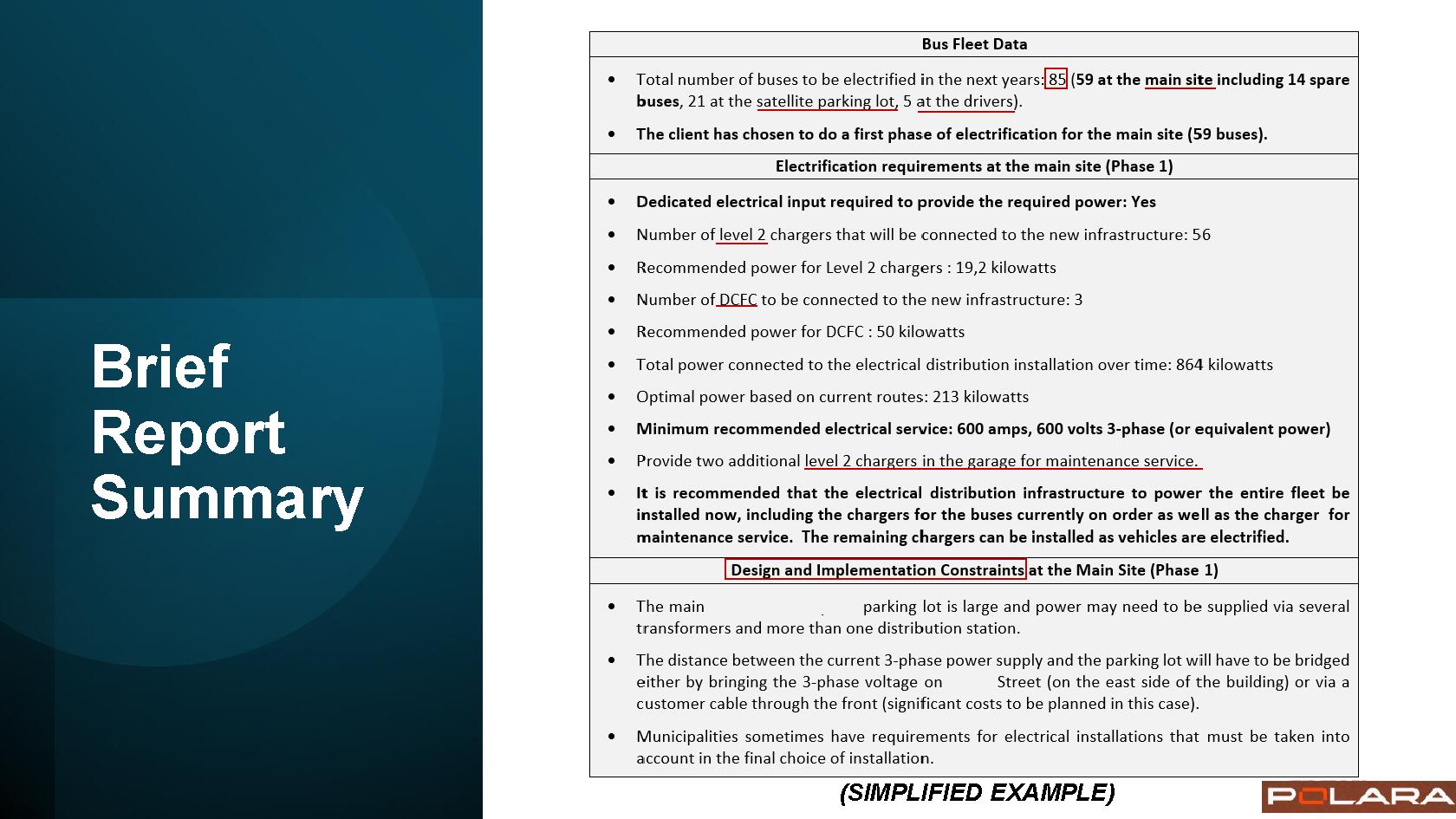

An engineering report will detail specification for the equipment required.

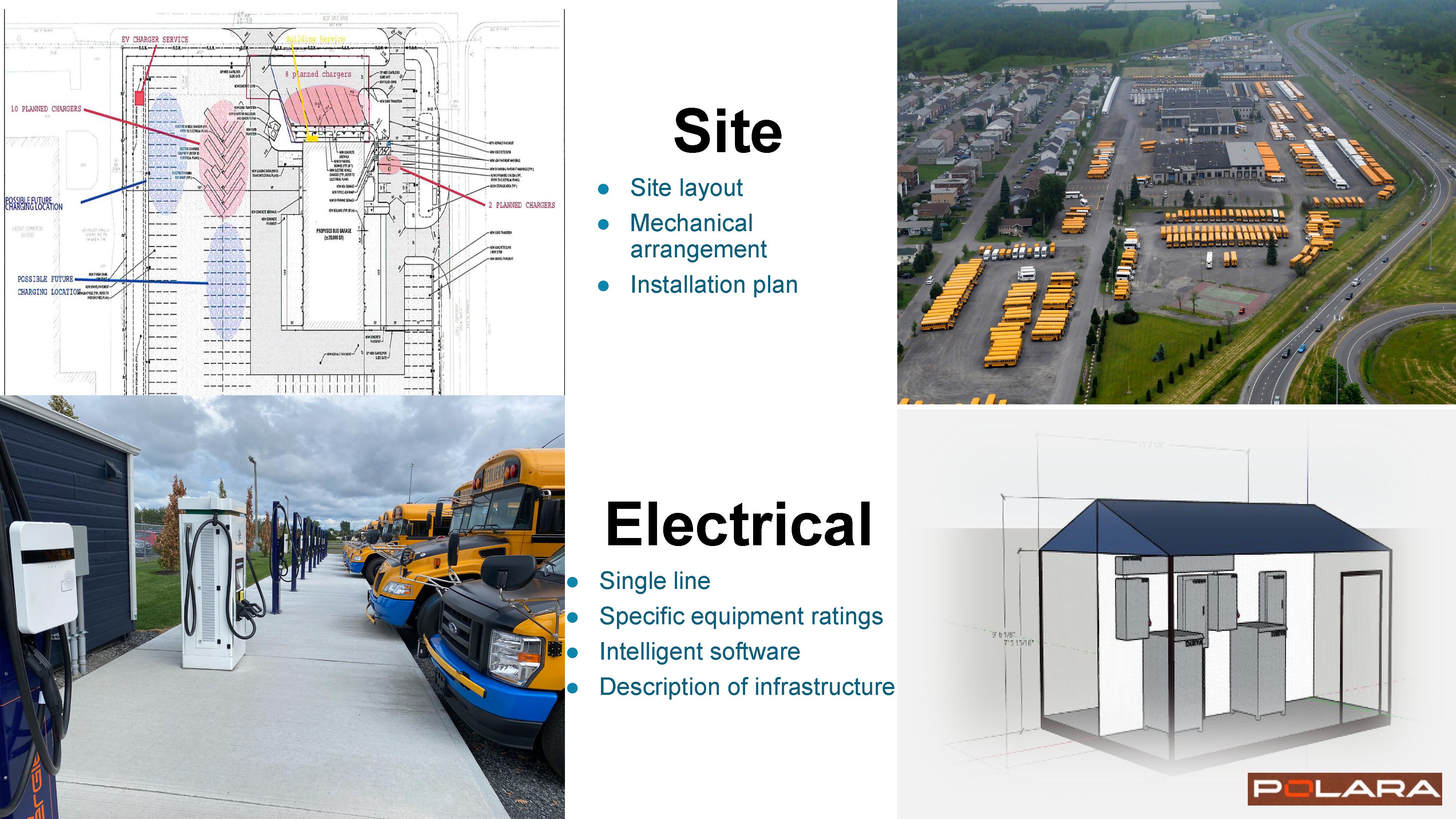

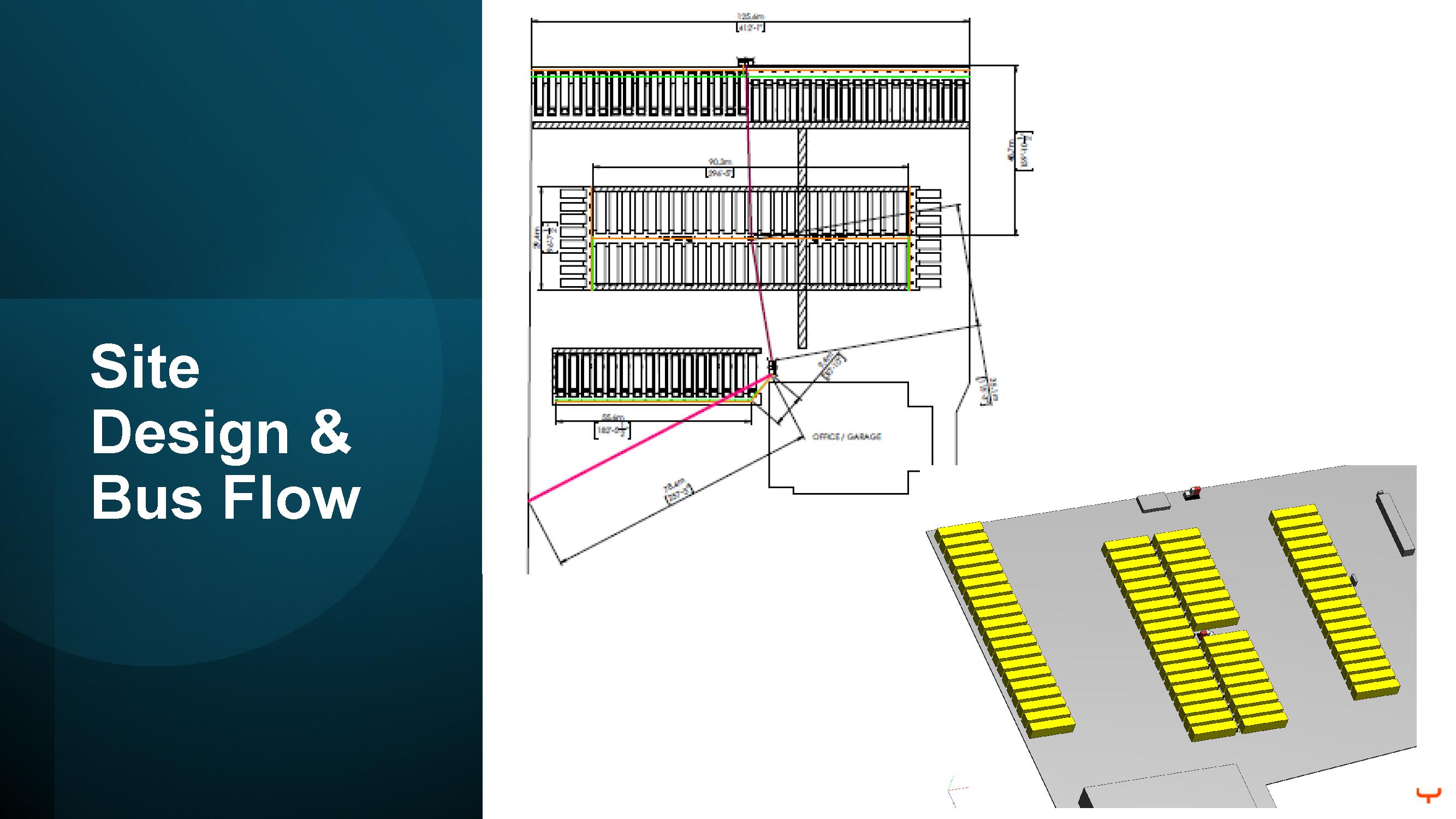

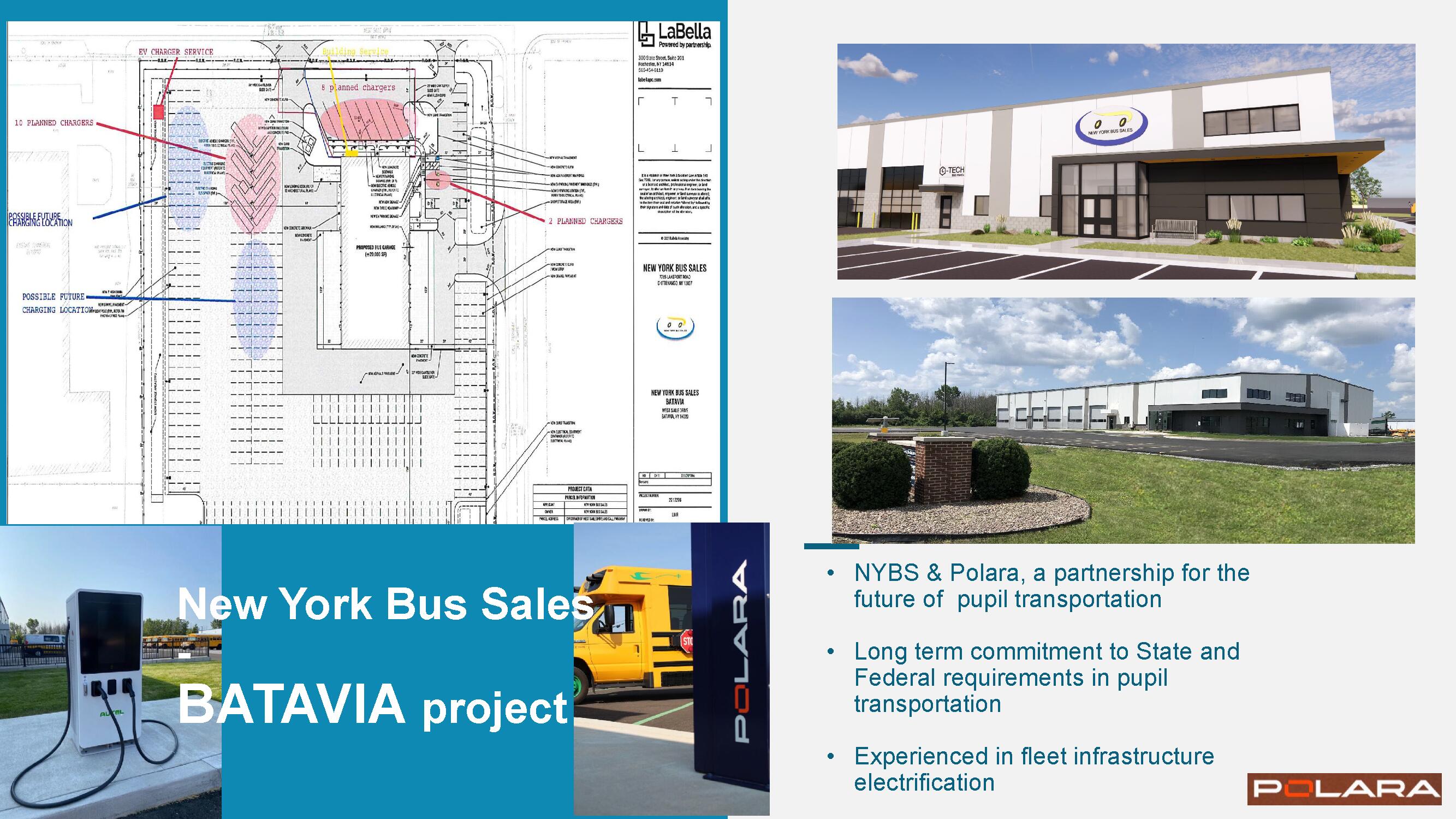

Site Work Would Include:

- Site layout, design and bus flow

- Mechanical arrangement

- Installation plan

Electrical Work Would Include:

- Single line

- Specific equipment ratings

- Intelligent software

- Description of infrastructure

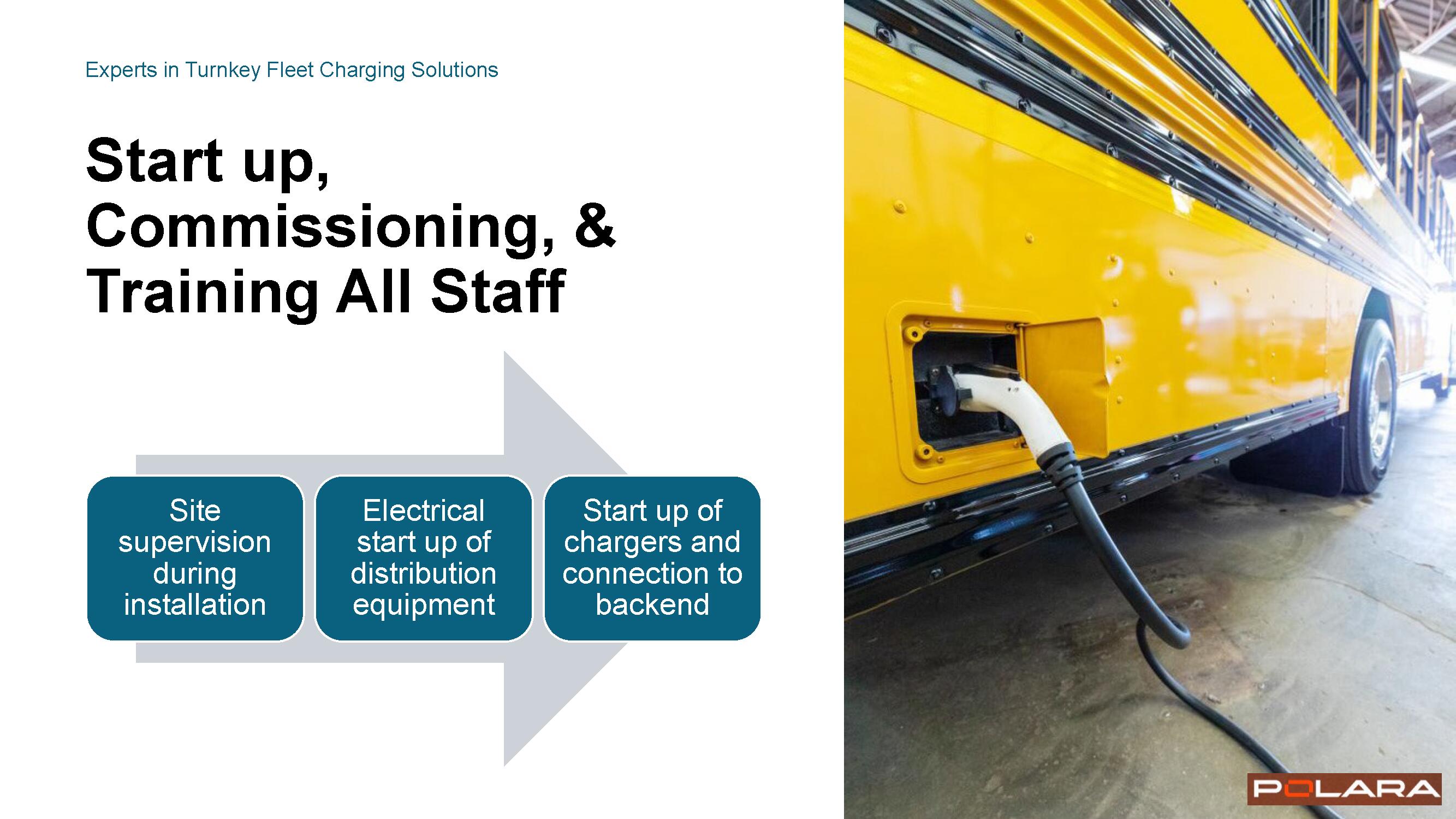

- Start up, Commissioning, & Training All Staff

- Site supervision during installation

- Electrical start up distribution equipment

- Start up of chargers and connection to back end

- Site supervision during installation

- Support

-

Infrastructure diagnostics response / resolution

-

Deployment time of onsite service

-

Preventative Maintenance

-

Spare Parts, Storage, and Availability

-

Battery Recycling

-

Standard and Extended Warranty Coverage

-

- Training

-

Electric Driving School

-

Charger Training Level 1: Operation

-

Charger Training Level 2: Maintenance

-

Banked Hours

-

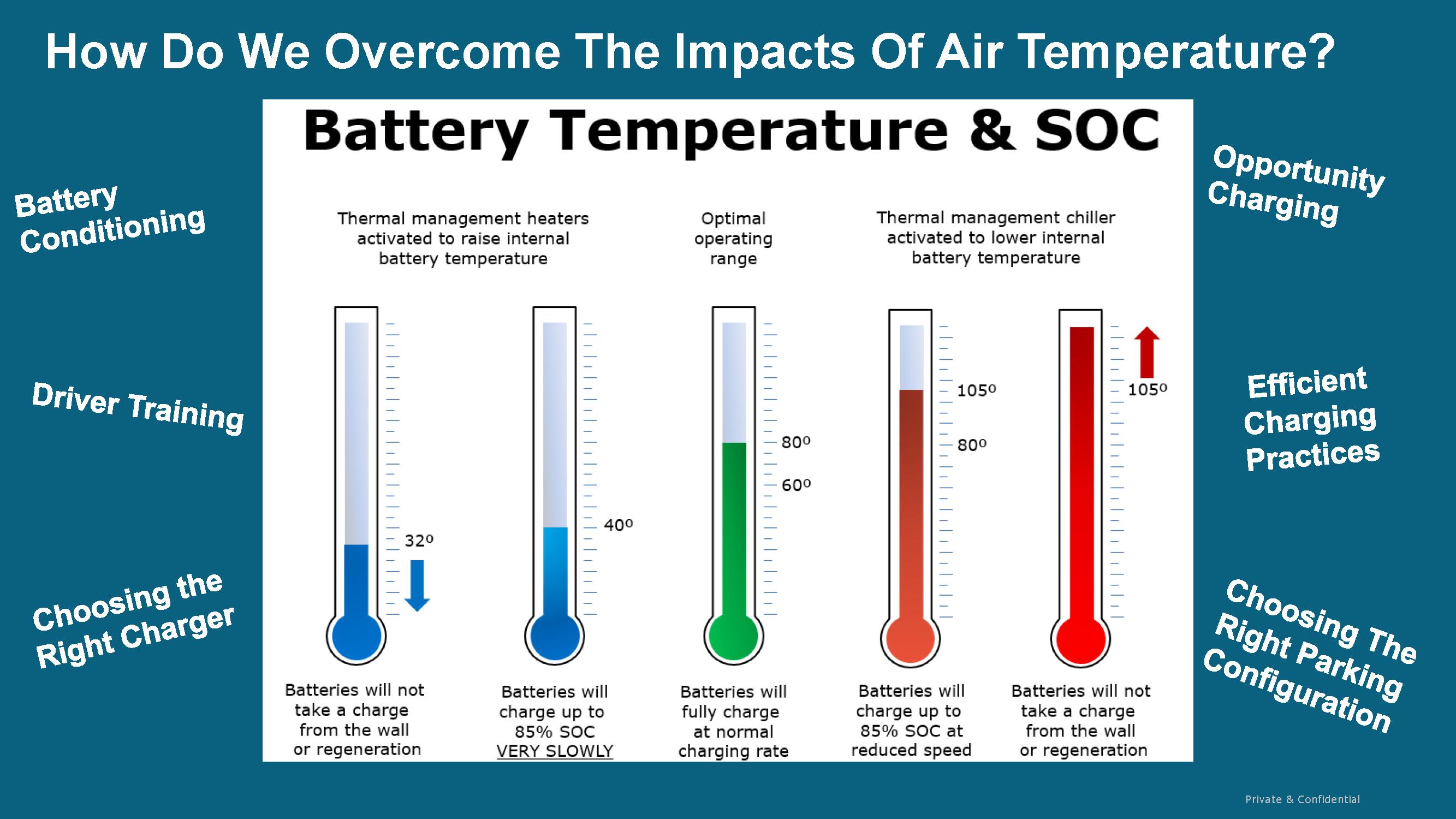

How do we overcome the impacts of air temperature?

- Battery Conditioning

- Driver Training

- Choosing the Rght Charger

- Opportunity Charging

- Efficient Charging Practices

- Choosing the Right Parking Configuration

Optimal Operating Range: Between 60 and 80 degrees, batteries will fully charge at normal charging rate (Optimal)

Thermal management heaters will be activated to raise internal battery temperature when needed because:

- Under 32 degrees: Batteries will not take a charge from the wall or regeneration

- Art 40 degrees: Batteries will charge up to 85% SOC (VERY SLOWLY)

Thermal management chiller will be activated to lower internal battery temperature when need because:

- Between 80 and 105 degrees, Batteries will charge up to 85% SOC at reduced speed

- Above 105 degrees, Batteries will not take a charge from the wall or regeneration

/LCSD_Logo_2022.png)

/Soule%20Road%20Middle.jpeg?mask=1)